Smart supply chains: Making IoT work

There are various key components of the IoT ecosystem that are needed to support the adoption of IoT solutions.

Edge computing could also be useful for predictive maintenance of machinery and equipment in factories.

The IoT inside supply chains

In terms of the actual devices, one could classify IoT hardware into two broad categories (1) shorter range IoT – which requires things like smartphone or a gateway to connect, or (2) cellular IoT where the device can be connected directly to the base station.

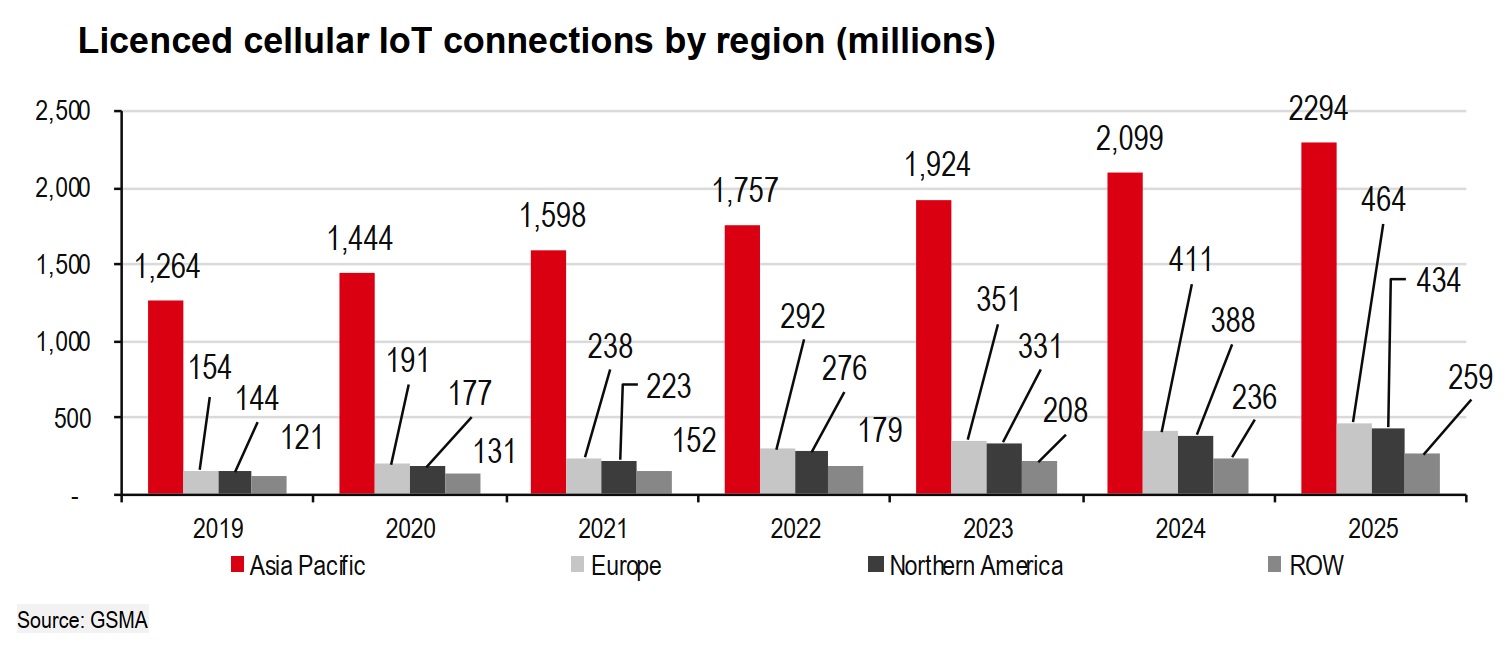

According to HSBC’s TMT team, there are now more than 160 commercial licenced LPWA (Low Powered Wide Area), and many of these will be NB-IoT (NarrowBand-Internet of Things) and LTE-M (Long Term Evolution for Machines) connections. These IoT connections are lower powered and the battery can typically last between 10-15 years. LTE-M has also typically higher

throughput than NB-IoT connections.

Applications for LTE-M include things like asset tracking in supply chains, for example shipping and pallet tracking – where roaming is required. NB-IoT applications include predictive maintenance for supply chains – where longer range is preferred, usually stationary to one specific region and which is easier for over-the-air updates.

Applications for LTE-M include things like asset tracking in supply chains, for example shipping and pallet tracking – where roaming is required. NB-IoT applications include predictive maintenance for supply chains – where longer range is preferred, usually stationary to one specific region and which is easier for over-the-air updates.

HSBC said the rollout of 5G will be key to enabling other technologies, including IoT, across various sectors. The integration of 5G aims to increase the efficiency of communications with a more robust network, data quality improvements and cost reductions – allowing sectors such as manufacturing to integrate advanced IoT technologies into their processes.

Increasing affordability of devices that power IoT solutions, such as sensors, will also help to spur uptake of this technology. For example, Business Insider Intelligence estimates that the average price of IoT sensors could fall below USD0.25 by 2025.

Tech components for IoT

IoT is projected to become a USD1,058bn market in 2030, growing at a CAGR of 10.2% from 2021 to 2030 according to Transforma Insights. Some of the largest demand drivers for IoT are in the consumer market (connected appliances, smart home, wearables, and more), and electricity, gas, steam & A/C markets. IoT by definition are electronic devices that are embedded in other objects, capable of connecting to wireless networks.

Some of the most prevalent connection protocols are NB-IoT, LTE Cat1, BLE 5.0, Wi-Fi, UWB, and 5G. Like any electronic device with connectivity, IoT products will need processors, sensors, memory, MCUs, PMICs, and RFIC as foundational building blocks.

Some of the most prevalent connection protocols are NB-IoT, LTE Cat1, BLE 5.0, Wi-Fi, UWB, and 5G. Like any electronic device with connectivity, IoT products will need processors, sensors, memory, MCUs, PMICs, and RFIC as foundational building blocks.

Chips shortage impact

The typical IoT product will likely use 22/28/45/90nm nodes as reliability and robustness are prioritized over computational capabilities. Under the current semiconductor environment, while advanced large-scale IoT products like TWS, smart watches, and home pods may still enjoy robust demand, smaller-scale IoT products will likely suffer in the near term.

With the ongoing foundry tightness, new IoT semiconductor tape-outs will likely be put on hold, as the ASP and volume of these products may not satisfy the already-tight foundries. Furthermore, consumers may be more price sensitive to the increasing cost of producing these IoT products as a result of price hikes from foundries, compared to industrial and commercial customers who are more price inelastic.

Edge computing to support growth of IoT

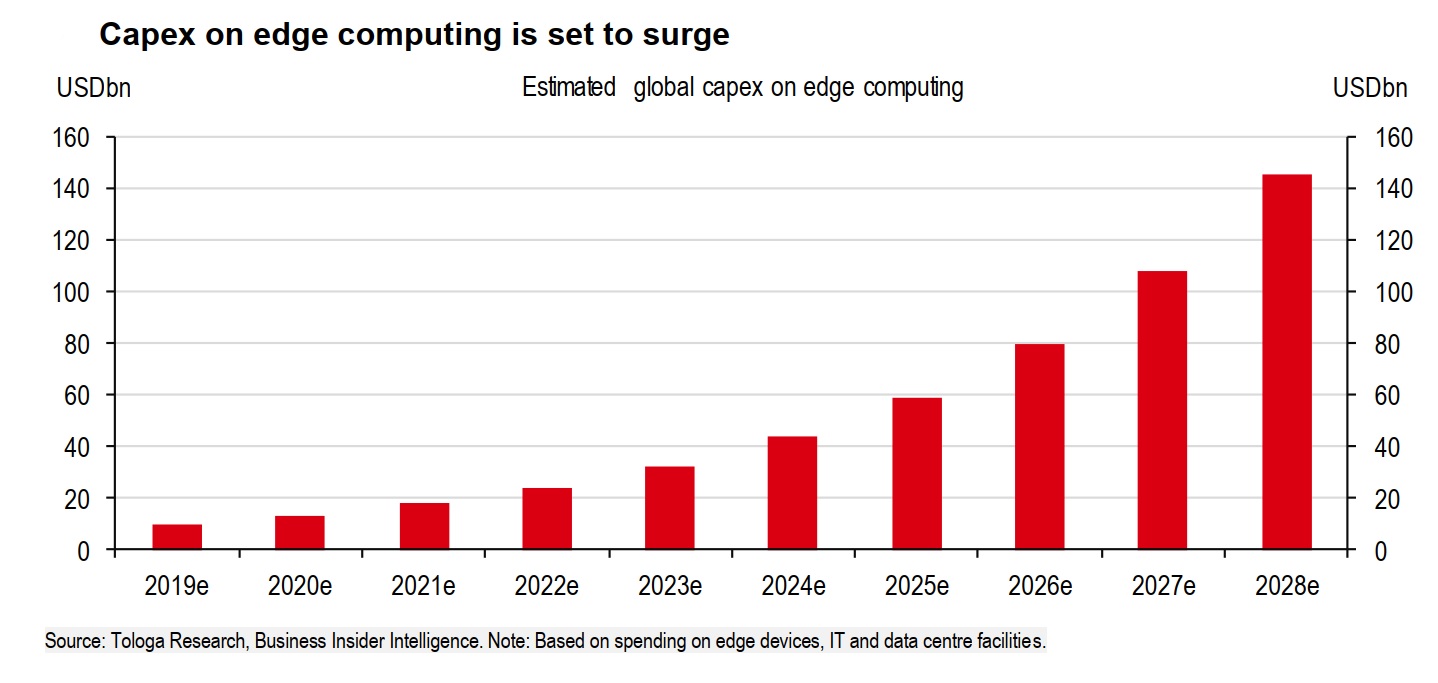

The growth in IoT devices is also set to generate huge amounts of data, which could affect how quickly the data are processed. Edge computing offers a solution to this latency problem by moving computing services closer to the source of the data (i.e. the IoT device). This enables data from the IoT device to be analysed quickly “at the edge” rather than sending it to a datacentre or to the cloud where it may take longer. According to Tologa Research, global capex on edge computing is set to rise from around USD10bn in 2019 to USD146bn by 2028.

Applications such as autonomous vehicles are a good example of where edge computing would be helpful, as a self-driving truck would need to collect and process information in real-time, without any lags in order to avoid an accident. 5G would be important in this instance too.

Edge computing could also be useful for predictive maintenance of machinery and equipment in factories, where high volumes of data are being generated and an immediate response is required if an imminent malfunction is detected. This can ultimately help businesses save on costs (both monetary and productivity-related) and mitigate future production disruption by preventing small issues from becoming a much larger problem.